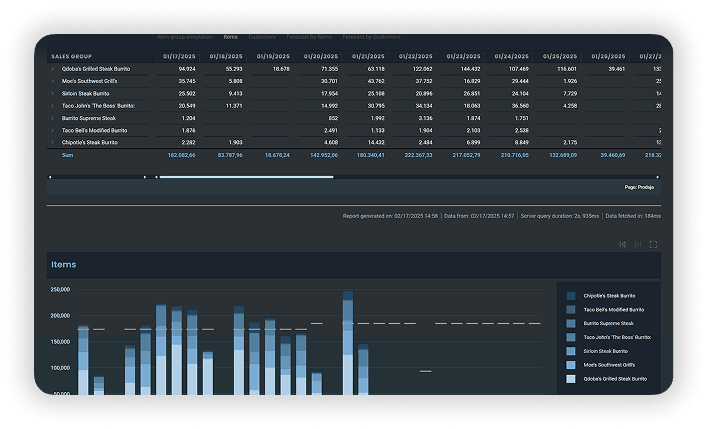

Food &

Beverage

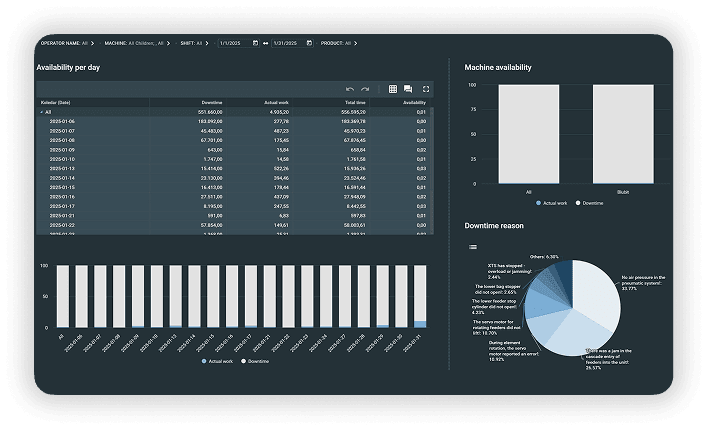

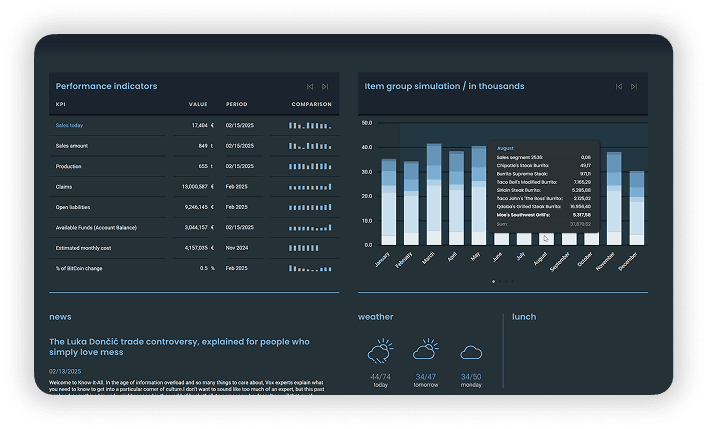

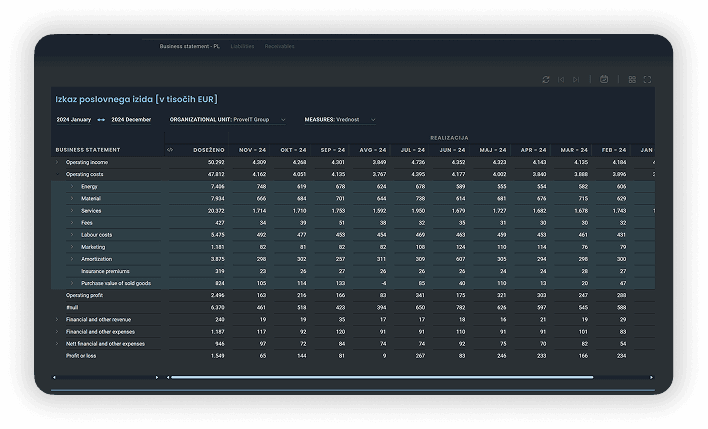

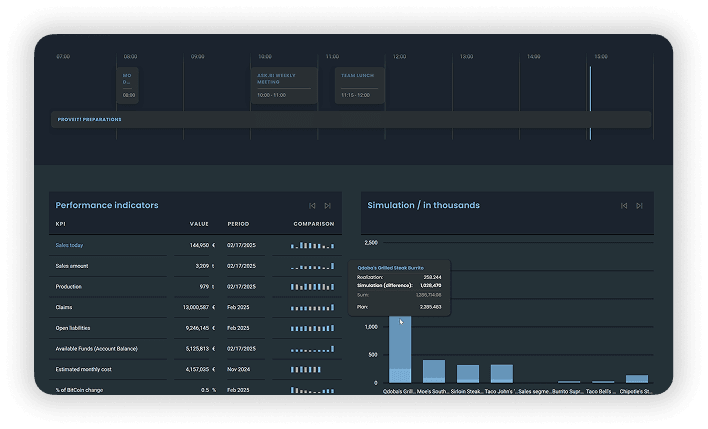

Use Case: Optimize production planning and inventory management, reduce waste and spoilage, ensure consistent product quality, and track key performance indicators like OEE (Overall Equipment Effectiveness).

Automotive

Industry

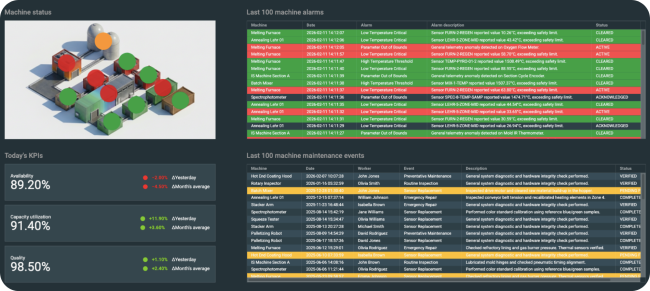

Use Case: Monitor production line performance in real-time, identify bottlenecks and inefficiencies, track quality metrics, predict equipment failures, and improve supply chain visibility.

Consumer

Goods

Use Case: Analyze sales trends, forecast demand, optimize inventory levels, track product performance, and personalize customer interactions based on buying behavior.

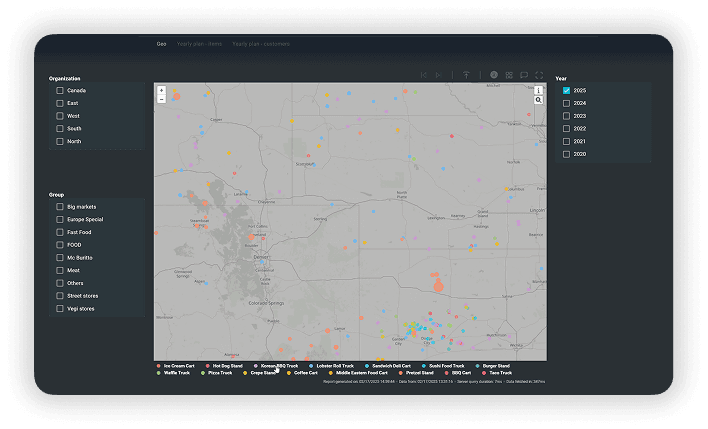

Logistics &

Distribution

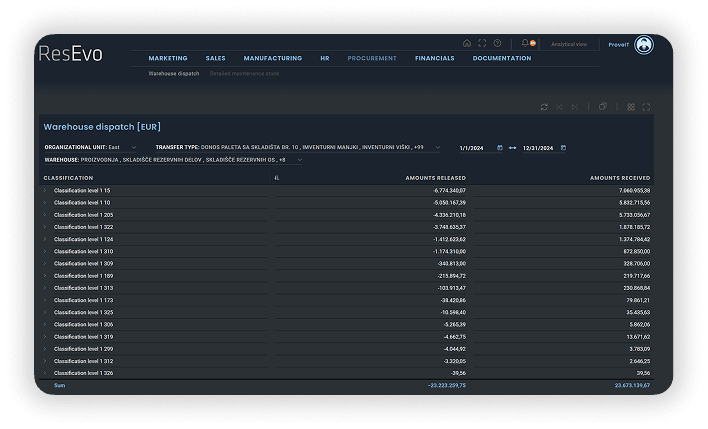

Use Case: Improve route optimization, track shipments in real-time, monitor warehouse inventory levels, and gain insights into delivery performance and customer satisfaction.